Home > Product > Grain Dryer > 5H-15 Rice Dryer

Rice Milling Machines

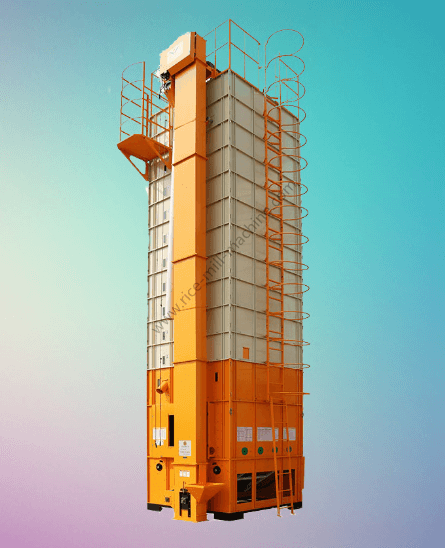

5H-15 Rice Dryer Machine

Drying paddy, wheat, corn,etc.

Capacity: 15 Ton per batch

Use biomass resources, such as husk

Lowest cost

Multiple safely devices

Description

5H-15 Rice Dryer Machine

This 5H-15 Rice Dryer is suitable for drying paddy, wheat, grams lentil, sorghum, soybeans and etc.

This rice dryer uses hot air as drying medium and adopts spinning circulation system design in order to save energy. In order to avoid overheating condition and ensure the quality of grain after drying, it’s equipped with automatic temperature sensor and moisture detector control.

Provided with furnace, using husk or chaff for main fuel, burning air through the heat exchanger to purify it and then dry it will not pollute the grain. Since it uses chaff for mail fuel, it is better for our environment and saves more money. And it’s efficient and user friendly.

Features 5H-15 Rice Dryer Machine:

1. To avoid grain being bud and mildew, rescue grain before raining;

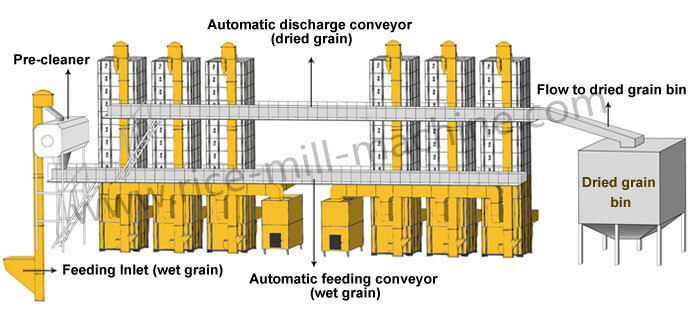

2. Saving drying space, reduce labor costs;

3. No matter in daytime, nighttime or raining, we also can provide 24 hours automatically drying and can produce few thousand tons per day by one man;

4. Low temperature leveling drying, ensuring even moisture and reduce rice cracking and rice broken;

5. Fine dryer produces rice with good quality and good mouth-feel;

6. Suitable for farm owner and for food merchandiser;

7. Most inexpensive, lowest cost dryer;

8. Our dryer is designed for seed and grain (rice), which can produce grain with highest price;

9. No oil, no coal, electric power saving;

10. Less maintenance needs, strong, enduring;

Our dryer can be equipped with husk furnace that used the biomass material for fuel, which can lower the cost.

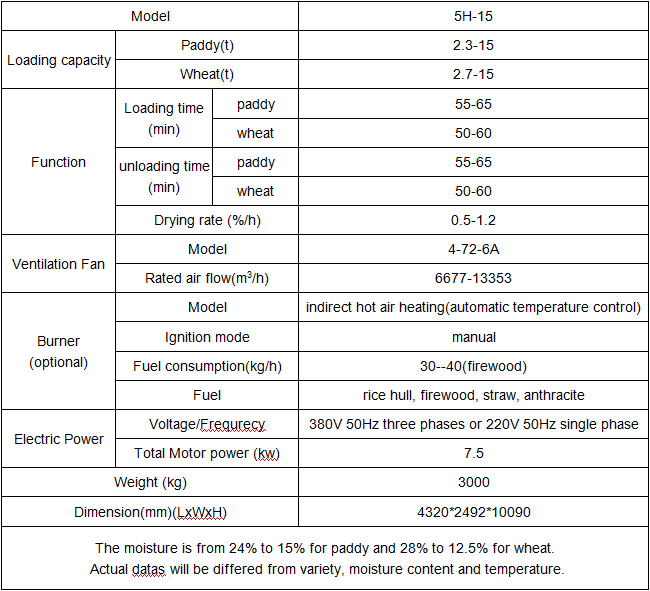

Technical parameters of 15t Rice drying machine:

Rice Dryer Machine Price:

Rice dryer price is different from capacity, voltage and frequency, please tell us your requirement, to let us send you best prices ASAP.

Related Products

REQUEST A QUOTE

Please tell us your detailed requirements, as capacity, quantity, destionation port, etc, so that we can quote you the best price.